DC igniters are important assemblies that provide heat at a particular temperature with the intention of starting a combustion reaction. They are widely used in industrial products such as burners, heated pressure washers, tar buggies, and can be used in steam cleaning and DC HVAC applications. Igniter manufacturers have the capabilities to design and produce standard and customized DC igniters for specific applications.

Types of DC Igniters

Generally, there are three common types of igniters that are used by numerous industries:

- Electrode or spark igniters

- Pyrotechnic igniters

- Hot surface igniters

These devices can be distinguished by certain features and characteristics.

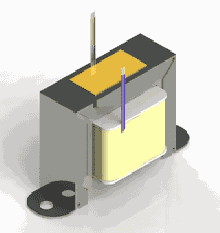

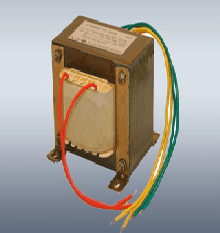

- Spark Igniters: Typically the most common igniter when igniting kerosene and diesel fuels. This type utilizes high voltage to create a very hot spark which is needed to ignite the flame in a burner or furnace. The DC igniter takes a DC voltage, typically 12V or 24V, chops it up into an AC voltage and steps it up significantly. This high voltage is placed across two electrodes that are a specific distance apart. When the voltage potential between the two electrodes reaches a critical point, a very hot spark is created between the two electrodes. This hot spark ignites any fuel in the fuel burn chamber.

- Pyrotechnic Igniters: This device derives its name from a pyrotechnic combination of powdered oxide and a metal known as thermite. They are basically used for applications that require complex ignition systems. They are designed to produce swift bursts of flames at high temperatures. However, the flames can only be concentrated to a small surface area.

- Hot Surface Igniters: Perhaps the most chemically advanced igniter type among the three products, this device is manufactured using high grade natural materials. The two most common materials used in manufacturing hot surface igniters are silicon carbide and silicon nitride. Silicon carbide is used because of its high resistance to oxidization. Silicon nitride is known for its durability at high temperatures. Thanks to these materials, hot surface igniters are known for their reliability, and are used in a variety of high grade hot water heaters and space furnaces.

Understanding the unique characteristics of each igniter can help you choose the best one for your industrial application.