Antenna coils, also known as air core transformers, are the primary transformers used in various types of electronic radio and communication devices. They are well-known for their use in small electronic applications such as radio transmission.

What makes Air Core Transformers Different from Other Types?

The function of an air core transformer is based on the induction between two magnetically linked coils or windings. The transformer consists of a primary and secondary winding coils.

The coils are generally constructed from insulated copper wire. The coils are wound on a non-magnetizing surface like cardboard or a plastic tube. There are certain points that makes air core transformers different from other types. They do not contain iron or ferromagnetic cores. Unlike electrical and power transformers, which utilize their cores to create a flux, air core transformers create flux using the windings and the air passing through them.

The advantage of this is that there is no distortion, no dissipation of signal quality, and noise free operation. Also, there are no losses in terms of hysteresis and eddy currents. The absence of a core also makes the air core transformer (Antenna coils) light in weight. These are the various reasons why air core transformers are chosen for small sized, portable electronic devices.

Air Coir Transformer Types

Generally, there are two primary forms of air core transformers used in electronic applications:

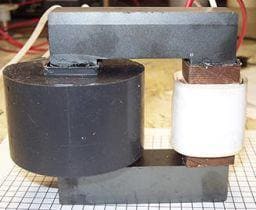

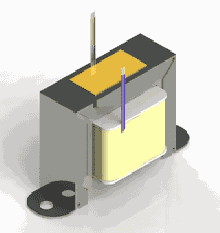

- Cylindrical Air Core Transformers: The name of this type of transformer comes from the fact that the insulated copper wires are wound on a cylindrical, hollow, non-metallic structure. This nonmetallic structure provides a certain amount of mechanical support to the windings. The primary copper coils are tapped at certain places. The secondary winding is wound across the taps. The taps, as well as the hollow cylinder allows the flux to flow through the air within the hollow cylinder, as well as the air encapsulating the winding.

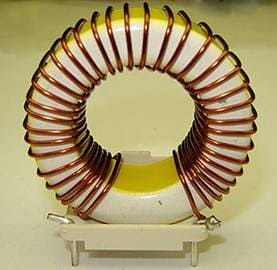

- Toroidal Air Core Transformers: In this air core transformer form, insulated copper wires are wound around a non-metallic ring, usually made from tough plastic. The coil is wound around the ring’s periphery. In toroidal air core transformers, each coil winding is utilized separately. This ensures that the effect of stray couplings is minimal. For this reason, toroidal air core transformers are generally used in applications consisting of high frequencies. The primary to secondary winding ratio varies, and depends on the operation type and change in frequency.

Enhancing/Maintaining the Performance of Air Core Transformers

There are certain steps that can be taken to maintain or enhance the performance of the transformer. In cylindrical transformers, a guard winding can be wound around the primary copper winding, to allow for effective impedance matching. Furthermore, the guard winding can be connected to antenna receivers to improve the transformers’ operation. Another method to improve the performance of the transformer is to connect a capacitor to the winding. This allows the winding to maintain a constant resonance of the tuning circuit.

Air core antenna coils follow the same working principle of other transformers. However, their lack of cores make them the perfect solution for small portable radios, and other communication devices.